Common Issues in Double Membrane Gas Holders

Qingdao Haiyue Biogas has focused on the research and application of biogas engineering for nearly 20 years since its establishment. Throughout our years of project practice, we have encountered various problems and challenges, ranging from equipment selection to sealing processes, and from pressure control to system optimization. Each step has provided us with invaluable experience. In this article, we will briefly explain the causes and solutions to these common issues, hoping to offer some reference for our peers and jointly promote the progress and development of the biogas industry.

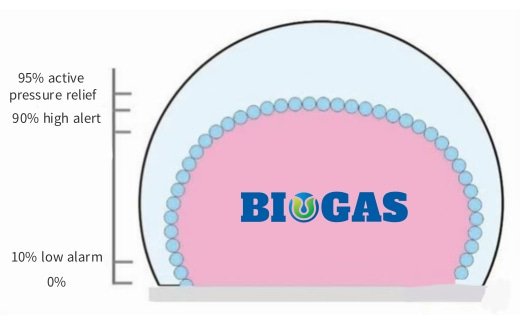

The bottom membrane, inner membrane, and outer membrane together form two sealed flexible spherical gas storage spaces. When the pressure in the inner membrane's intake pipeline exceeds the set pressure of the outer membrane, the outer membrane control device automatically releases air from the outer membrane, allowing the inner membrane to intake gas effectively. When the pressure in the inner membrane's exhaust pipeline falls below the set pressure of the outer membrane, the outer membrane control device automatically activates the fan to inflate and maintain the protective pressure of the outer membrane.

Note: When ambient temperature changes, the pressure of the outer membrane will also fluctuate accordingly; the fan will automatically run or release pressure as needed.(such as morning sun exposure or evening temperature drop, etc.)

The water seal functions as an overpressure protection device to prevent overpressure in the gas holder under unexpected circumstances, thereby protecting the inner and outer membranes. Safety water seals are typically equipped with a sight glass for users to periodically check the water level.

The water seal in a gas holder serves two main purposes: first, to prevent gas backflow in the gas holder's inlet and outlet due to water level changes, maintaining the stability of compressed air; second, to prevent external moisture from entering the compressed air in the gas holder, protecting the gas holder.

pecifically, the inlet and outlet water seals of the gas holder generally consist of an inlet, outlet, water seal, water level gauge, and pressure regulator. When the water level rises or falls, the water level gauge detects the change and controls the opening and closing of the water seal to adjust bubble size, thereby controlling the gas flow at the inlet and outlet. As the bubble size changes, the pressure regulator automatically adjusts air pressure by controlling the opening and closing of the intake or exhaust ports. This ensures that the compressed air in the gas holder maintains appropriate pressure and airtightness, preventing water and moisture from entering the gas holder and ensuring both gas holder protection and the normal operation of the system.

Qingdao Haiyue has been specializing in biogas equipment for nearly 20 years and has rich experience. The equipment includes but is not limited to double membrane gas holders, enamel assembled tanks, etc. Can be used for sewage treatment, large-scale kitchen waste treatment, industrial projects, etc. If you are interested in this, you can contact us.

Please contact hykurttian@gmail.com