Introduce the dual membrane gas holder from multiple aspects

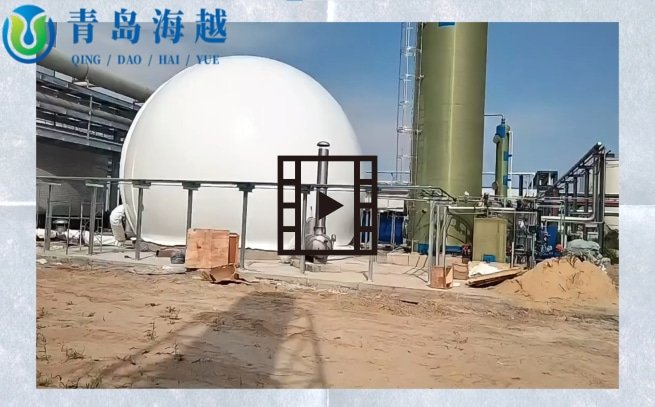

The double membrane gas holder is a durable air-supported structure designed specifically for the storage of biogas.Typically, gas holders are installed as part of anaerobic digestion systems in wastewater treatment plants , agricultural digestion projects , landfill sites , and cogeneration plants that utilize biogas generated from organic materials as an energy source. The double membrane gas holder is primarily composed of three components: the outer membrane , inner membrane , and base membrane . The outer membrane serves a protective role for the system . Even under extreme conditions such as storms , the outer membrane continuously withstands positive pressure to maintain hydrostatic equilibrium . The inner membrane is used for storing biogas and expands or contracts based on the gas volume. The base membrane separates the foundation from the inner and outer membranes . Both the inner and outer membranes are made from specialized high quality biogas membrane material , possessing qualities such as UV resistance, aging resistance, abrasion resistance, methane permeation resistance, and a certain level of self-cleaning capability.

It is understood that commonly used biogas stabilizing holders include double membrane gas holders, floating roof holderss, and wet gas holders. Generally speaking, biogas is produced continuously, but there is heterogeneity between biogas production and utilization, and a balance between biogas production and consumption. Therefore, a storage device is needed to store unused biogas in subsequent process stages (biogas generators, boilers, etc.).

The application fields of biogas stabilizing holders are quite extensive, including light industries such as starch, papermaking, alcohol, fermentation, dairy products, etc; It is also used in other industries, such as steel, coal chemical industry, landfill leachate, etc.

(Click on the image below to jump to the video)