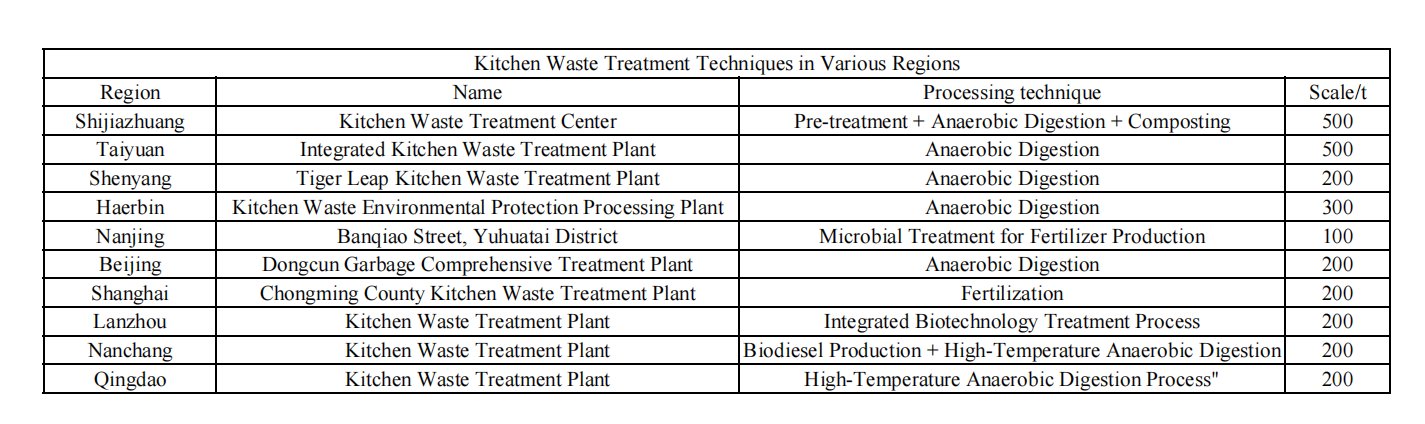

Application Status of Anaerobic Digestion Technology in Treating Kitchen Waste Currently, anaerobic digestion is widely regarded as a suitable technology for treating kitchen waste to generate biogas. According to statistics, the majority of domestic kitchen waste treatment projects employ anaerobic digestion processes. The table below illustrates the situation of some domestic pilot cities' facilities for kitchen waste treatment. Approximately 50% of kitchen waste treatment processes utilize anaerobic digestion technology.

Despite the widespread application of anaerobic digestion technology in China, which has effectively improved the environmental pollution caused by kitchen waste, the process of anaerobic digestion itself also generates pollutants and faces challenges in treating sludge and liquid residue. Anaerobic digestion of kitchen waste not only produces biogas but also various organic acids, alcohols, and hydrogen, achieving the resource utilization and reduction of kitchen waste. However, gases such as hydrogen sulfide, ammonia, and sulfur dioxide in biogas, when mixed with volatile fatty acids released into the atmosphere, contribute to malodorous emissions. Therefore, if sludge and liquid residue are discharged indiscriminately, it not only leads to the loss of nutrients but also causes secondary pollution to the environment.

Characteristics of Anaerobic Digestion Residues from Kitchen Waste

Nutrient Characteristics

After separation, residues from anaerobic digestion of kitchen waste form sludge and liquid residue, which still contain a large amount of nutrients, including organic matter and humic acids. The organic matter content in residues from anaerobic digestion of kitchen waste ranges from 33% to 73.3%. After dehydration, the organic matter content in sludge ranges from 61.7% to 73.6%. Research indicates that the soluble nitrogen, phosphorus, and potassium content in the liquid residue are 0.124 wt%, 0.0063 wt%, and 0.026 wt%, respectively.

Sludge and liquid residue contain abundant nutrients such as nitrogen, phosphorus, and potassium required for plant growth. Different digestion substrates may result in differences in the components and concentrations of residues. For example, residues from anaerobic digestion of straw contain nitrogen, phosphorus, and potassium at concentrations of 41.3 g·kg^−1, 31.02 g·kg^−1, and 12.75 g·kg^−1, respectively. Residues from anaerobic digestion of livestock and poultry manure contain nitrogen, phosphorus, and potassium at concentrations of 17.41 g·kg^−1, 31.02 g·kg^−1, and 12.75 g·kg^−1, respectively. We analyzed the composition and basic characteristics of sludge and liquid residue from anaerobic digestion of kitchen waste, with carbon (C), hydrogen (H), oxygen (O), and nitrogen (N) contents at 38.79%, 5.28%, 20.83%, and 7.28%, respectively. The high carbon content indicates that organic matter is not completely degraded during anaerobic digestion, and there is still some value in utilizing the sludge and liquid residue from kitchen waste anaerobic digestion.

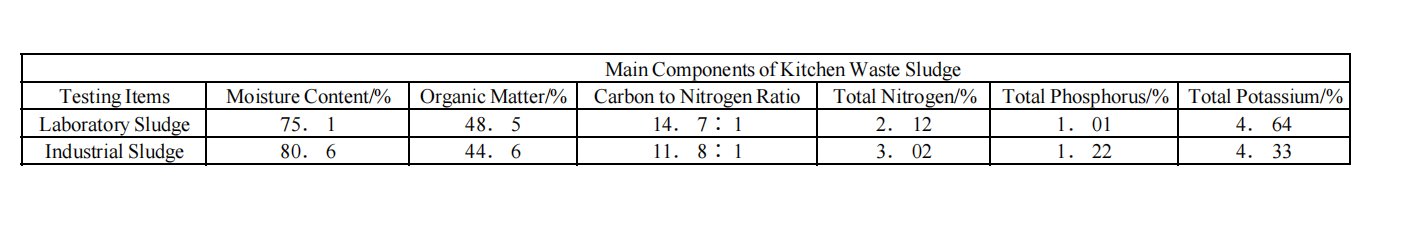

We conducted component analysis of sludge from anaerobic digestion of kitchen waste in a laboratory and compared it with the composition of sludge fermented in industrial facilities. Results show that differences in raw material sources lead to variations in composition. Additionally, sludge contains constant elements such as sodium, magnesium, and calcium, as well as trace elements like iron, zinc, and copper. Application of sludge to soil can improve soil structure and promote crop growth. Furthermore, since anaerobic digestion residues are produced in the presence of microorganisms, sludge and liquid residue may contain pathogens such as Salmonella, Escherichia coli, Enterobacteriaceae, and intestinal parasites. Therefore, there is a risk of pathogen contamination in sludge and liquid residue.

For more exciting content, please refer to the next article.

Data comes from the China biogas.