Enamel Assembled Tanks and Epoxy Resin Tanks

The New Choice for Efficient and Durable Storage In the field of industrial storage, the choice of materials is crucial for achieving durability, efficiency, and cost-effectiveness. Two popular types of tanks – enamel assembled tanks and epoxy resin tanks – are setting new standards for storage solutions across various industries, including biogas, wastewater treatment, and chemical storage. Each tank type offers unique benefits suited to different environmental conditions and operational requirements.

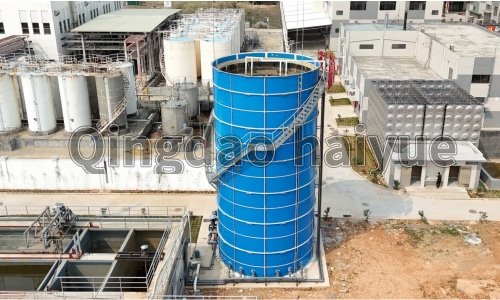

Enamel Assembled Tanks are renowned for their strength and resilience. Constructed with steel plates coated with a layer of enamel, these tanks provide superior corrosion resistance. The enamel coating creates a barrier that protects the steel from chemicals, high temperatures, and humidity, ensuring the tanks can withstand harsh environmental conditions. Additionally, the modular design of these tanks allows for easy assembly, transport, and expansion, making them an ideal solution for projects that require flexibility and scalability. Enamel assembled tanks are particularly well-suited for applications like wastewater treatment and biogas storage, where consistent durability is essential.

Epoxy Resin Tanks, on the other hand, are highly valued for their lightweight and versatile nature. Epoxy coatings offer exceptional resistance to corrosion, especially in acidic or alkaline environments. Unlike other materials, epoxy resin has a smooth, seamless surface that is easy to clean and reduces the buildup of contaminants, thus maintaining the purity of stored substances. These tanks are a preferred option for environments where hygiene and chemical resistance are priorities. Industries dealing with sensitive chemicals or clean water storage often favor epoxy resin tanks for their non-toxic, non-reactive qualities.

Both enamel assembled tanks and epoxy resin tanks provide efficient, long-lasting storage solutions tailored to meet diverse needs. With their distinct strengths, they cater to various operational requirements and contribute to more sustainable, reliable storage practices in modern industrial applications.